|

Solution: AI inferencing at the edge for power- and cost-efficient defect detection

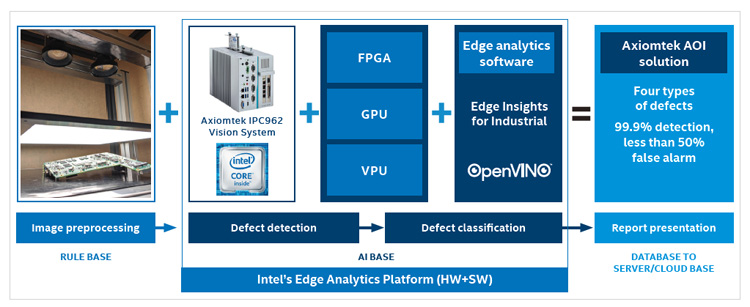

To optimize for cost-effectiveness and power utilization, Axiomtek developed its AOI solution for PCBA using edge technology to bring compute resources closer to the devices capturing images. Images are preprocessed, then defects are detected and classified using AI algorithms. Out of the box, the system is able to detect four types of defects: short circuits, too much solder, too little solder, and empty solder. The accuracy of the system to detect defects grows as additional training images are added, with internal tests showing a detection rate of up to 99.9 percent.

All suspected problematic solder joints are marked with the result shown on a monitor for human inspectors to check. This accelerates the manual visual inspection process by directing the inspector’s attention only toward the anomalies, which are the joints suspected of quality issues. All suspected problematic solder joints are marked with the result shown on a monitor for human inspectors to check. This accelerates the manual visual inspection process by directing the inspector’s attention only toward the anomalies, which are the joints suspected of quality issues.

In addition to using its new AOI technology for its own production lines, Axiomtek plans to scale the solution to other manufacturers. These manufacturers will be able to adopt the visual processing and analysis algorithms developed by Axiomtek to detect additional issues based on their unique production needs.

Benefits of the Axiomtek AOI solution include:

Lower costs for data transmission and power consumption: By moving image processing and defect detection and classification to the edge, the amount of data transmission and power consumption required for AOI is significantly reduced: from 250W power usage using the NVIDIA GTX 2080 to less than 30W with the Intel® Movidius™ VPU.

Multiple defects types detected: A single unit can detect four different types of defects out of the box,2 and the visual detection algorithms used by the Axiomtek AOI solution can also be used to detect additional defects when trained with images of circuit boards with and without the specified defect.

Improved productivity: Automating defect detection in the production line makes inspection faster2 and can maintain consistent accuracy without being subject to human fatigue or errors from subjective observation

How it works in brief

Detecting defects with the Axiomtek AOI solution begins with the ingestion of training data. Thousands of images are used to improve the performance of AI algorithms detecting each defect type. To optimize the effectiveness of detection, the distance and angle between training data objects and cameras must be as close as possible to real-world testing conditions.

The Axiomtek AOI solution uses an Intel® Core™ processor-based platform as well as Edge Insights for Industrial, which allows easy integration of data, devices, and processes in manufacturing applications, enabling near-real-time intelligence at the edge. This allows manufacturers to achieve greater operational efficiency for factory use cases, including defect detection. In addition, the Intel® Distribution of OpenVINO™ toolkit enables the Axiomtek AOI solution to be deployed with existing Intel® hardware, as well as flexible, heterogeneous computing depending on the power and performance required for the needs of each product and process.

Multiple camera types can be used for image intake. USB cameras, Basler cameras, and RTSP cameras can be connected quickly and easily using the camera software development kit included in Edge Insights for Industrial. Axiomtek uses Basler cameras in its own solution. Using Edge Insights for Industrial, Axiomtek was able to develop its own application quickly, allowing the capture of images and camera events. Once the most complex image capture problem has been solved, users can rapidly continue on to training and inference, and eventually deploy the AOI solution to deliver business results.

|