|

|

| |

| |

|

The oil and gas industry is eager to be freed from proprietary systems

|

|

| |

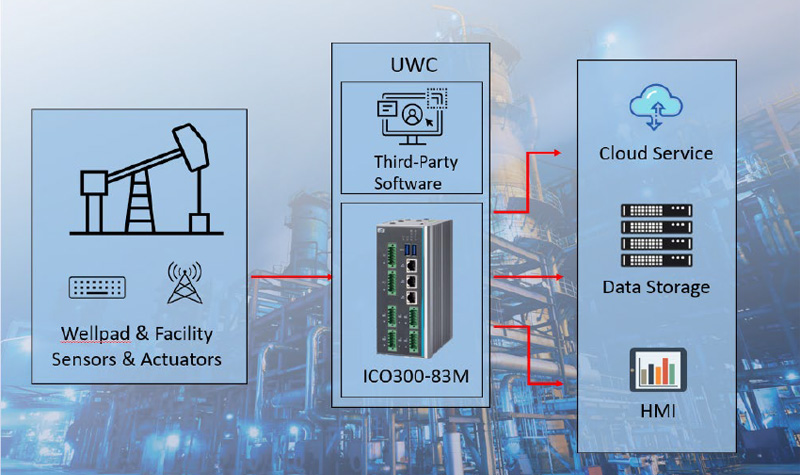

For decades, oil and gas company operations have been limited and monopolized by proprietary automation and control systems. These closed control systems are expensive to maintain, difficult to upgrade, and lack interoperability. Oil and gas companies are eager for a solution that transforms the automation and control of wells and facilities to help companies reduce costs, optimize productivity, and are not constrained by a few vendors. The adoption of Industrial IoT technology such as the Universal Wellpad Controller (UWC) can transform the industry.

|

|

|

| |

|

Intel and a gigantic energy company have orchestrated the Universal Wellpad Controller that leverages off-the-shelf hardware and open-source middleware software to provide an innovative solution that brings cost-effective, interoperable automation and control to onshore oil and gas operations. The Universal Wellpad Controller requires the hardware platform powered by the Intel x86 architecture. Most important, the edge computing platform must come with ATEX and Class I Division 2 (CID2) certifications to meet many required world safety standards important to the oil and gas industry.

|

| |

| Main Requirements |

- Low power consumption Intel®-based platform

- ATEX/CID2 certifications for harsh environment

- Data collection with Modbus

- Prioritized data exchange pathways for process control data

- Connectors for device management, Supervisory Control and Data Acquisition (SCADA), and backend data systems

- Industrial grade extended operational temperature for outdoor application

|

| |

|

The rugged industrial gateway realizes Industrial IoT for the oil and gas industry

|

|

| |

|

Axiomtek proposes the ICO300-83M for the UWC; the ICO300-83M is an ATEX, Class I Division 2 (CID2) certified DIN-rail fanless IIoT embedded controller for hazardous environments where ignitable concentrations of flammable gases or liquids might exist. It is powered by the Intel Atom® x5-E3930 processor with 8GB DDR3L-1866 RAM. For operation in harsh industrial environments, the IP40-rated gateway has a wide operating temperature of -40°C to 85°C, 9 to 36 VDC wide voltage input with OVP, UVP, OCP as well as RPP, and up to 3G vibration endurance. In addition, a cold boot at -40°C is available to help eliminate issues affecting the operational reliability of the system. The TPM 2.0 is also available to ensure critical information security. Axiomtek proposes the ICO300-83M for the UWC; the ICO300-83M is an ATEX, Class I Division 2 (CID2) certified DIN-rail fanless IIoT embedded controller for hazardous environments where ignitable concentrations of flammable gases or liquids might exist. It is powered by the Intel Atom® x5-E3930 processor with 8GB DDR3L-1866 RAM. For operation in harsh industrial environments, the IP40-rated gateway has a wide operating temperature of -40°C to 85°C, 9 to 36 VDC wide voltage input with OVP, UVP, OCP as well as RPP, and up to 3G vibration endurance. In addition, a cold boot at -40°C is available to help eliminate issues affecting the operational reliability of the system. The TPM 2.0 is also available to ensure critical information security.

To integrate signals from sensors and devices, the ICO300-83M has six isolated RS-232/422/485 serial ports; for controlling purposes, it also provides one 8-in/8-out DIO port. Furthermore, it features one HDMI port, two USB 3.0 ports, and three isolated Gigabit Ethernet ports. The ICO300-83M also comes with one mSATA occupied with a PCI Express Mini Card slot, an internal 2.5” SATA drive, and an optional eMMC on board. Moreover, it supports one M.2 Key B 3052 and one full-size PCI Express Mini Card slot for LTE or Wi-Fi modules to ensure superior connectivity for real-time communications. It is also equipped with a half-size PCI Express Mini Card slot and two SIM slots to maximize efficiency.

The powerful Universal Wellpad Controller edge controller from Axiomtek helps enterprises in the oil and gas industry gradually move on from the proprietary devices and embrace more advanced and cost-effective new technology.

|

| |

|

Application: Axiomtek propels the automation and management of the oil and gas industry

|

| |

|

|

Axiomtek provides the rugged Intel®-based IoT gateway controller, ICO300-83M, to the customers as an edge control device for the well and surface field facilities. The interoperable solution allows new types of sensors and software to be integrated and can give the operators real-time analytical parameters through open and extendable protocols and then initiate optimization and enhance operational efficiency.

|

| |

| System Configurations of the ICO300-83M |

|

- ATEX/Class I Division 2 (CID2) certified

- Cost-effective with fanless design

- Intel Atom® x5-E3930 processor (codename: Apollo Lake)

- 6 isolated COM, isolated DIO (8-in/8-out), and 3 GbE LAN

- Wide operating temperature range from -40°C to +85°C

- 9 to 36 VDC, typical 12-24V power input with OVP, UVP, OCP, RPP

- Supports TPM 2.0

- Supports cold boot at -40°C

|

| |

|

|

| |

|

By using standard off-the-shelf hardware such as Axiomtek's ATEX, Class I Division 2 (CID2) certified ICO300-83M DIN-rail IIoT controller, together with open architecture OS and edge analytical software, the oil and gas industry now has a unique solution that solves its long-term problems. Smart edge controllers from Axiomtek based on Intel® architecture enable oil and gas applications which help improve access, manageability, and analytics for better performance.

|

| |

|

*Source Intel Universal Wellpad Control

https://www.intel.com/content/www/us/en/energy/intelligent-wellpad-control.html

|

| |

|

|

|