|

Abstract

The importance of automation in the process industries has increased dramatically in recent years. In some highly industrialized countries, process automation is used to enhance product quality, master the range of products and efficiently, utilize resources and lower fewer emissions. In the rapidly developing countries, mass production has become the main motivation for applying process automation.

The importance of automation technology continues to increase in the process industries. The traditional barriers between information, communication and automation technology are, in the operational context, gradually disappearing. The latest technologies, including wireless networks, fieldbus systems and asset management systems, boost the efficiency of process systems.

Future Technology Trend in Automation

The global in industrial automation market will reach approximately $200 billion or more after 2015 according to Berg Insight. Asia is the biggest market of industrial automation products, accounting for almost half of the world market. Hence, there are two major factors are expected to change the style of the industrial automation. One is Energy Efficiency and another is Smart Technology.

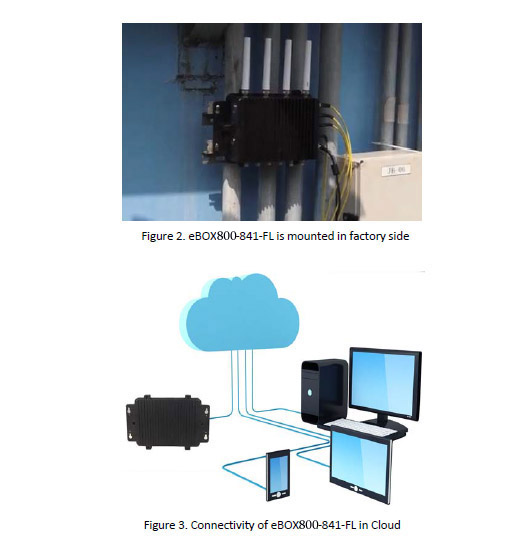

The factory of the future is with cloud computing, cyber-security and mobile communications technology to achieve higher productivity and efficiency andimprove effective interaction between an enterprise and its downstream clients, so that the customers can gain competitive advantage. Besides, asset management and flexible manufacturing are expected to integrate plant and enterprise.

Axiomtek eBOX800-841-FL System Design Features

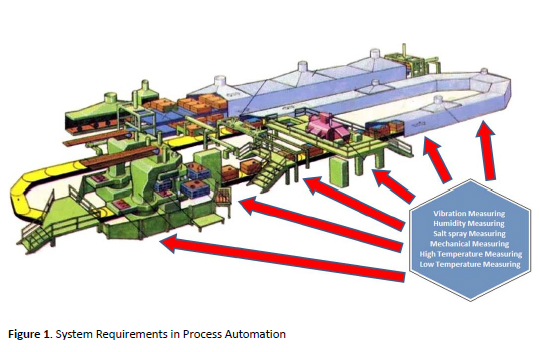

Industrial 4.0 is now the most important trend and concept, and the application of smart factory has increased dramatically. The Axiomtek eBOX800-841-FL is designed with the cloud concept and equipped with WLAN, Ethernet, 3G features. All data can be transmitted over the wireless, sending and receiving treatment in a timely manner. It also can through the Big-data to analyze and predict the status. (refer to Figure 1).

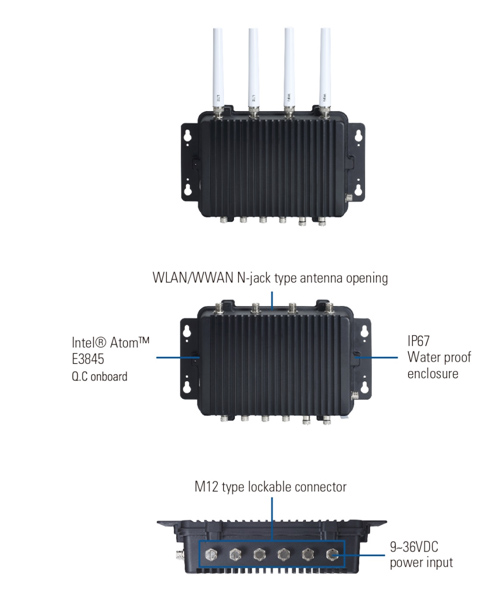

We know that machine condition monitoring (MCM) is used to prevent unexpected breakdowns, optimize efficiency, and short maintenance time and costs. Especially for large industrial plants such as steel mills, the MCM is the best solution. The Axiomtek fanless embedded box computer, eBOX800-841-FL, provides a complete IP66/IP67 waterproof solution for MCM application. The rugged embedded system adopts quad-core Intel® Atom™ processor E3845, the high efficiency and low power consumption (10W) CPU, and M12-type I/O connectors. It utilizes user-friendly fanless design to prevent the damage of CPU & system fan as well as create a noise-free environment. In the meanwhile, the maximum operating temperature is up to 60°C (0°C ~ 60°C).

The eBOX800-841-FL provides several I/O ports to meet the demand for network connections, DIO control and RS-232/422/485 data transmission. Besides, it reserves two standard Mini PCI Express slots and one CFast™ slot for expansion capability. Users can easily add expansion cards to build out their application; for example, the analog IO cards, A/D convert cards or D/A convert cards. In addition, the Intel® Atom-based eBOX800-841-FL supports IP66/IP67 waterproof specification which is specially designed for industrial environments and harsh environments (refer to Figure 2 and Figure 3).

User can use built-in expansion slot to set up AIO/DIO/AD data acquisition control card to receive related data from large machines in the factory accurately, such as temperature, humidity, vibration and noise level.

The eBOX800-841-FL is equipped with the Bay Trail platform Intel® Atom™ processor E3845, capable of integrating the data, and through built-in WiFi/3G wireless functionality to transfer the data to "Big data" as statistics and integration to facilitate long-term monitoring and analysis. Figure 4 summarizes the key features including communication, I/O extension and protection.

The collected data can be used to analyze the health of machines and surrounding operation environment to determine generating an alert, prior partial repair or replacement of the device. It also helps to eliminate machine downtime which will cause great loss. The eBOX800-841-FL provides a standard RS-232/422/485 port which is suitable for many data acquisition applications in heavy duty industries. Besides, the 8 USB ports support the extension of the application of I/O devices, strengthening the function of more expanding operations. The eBOX800-841-FL has IP66/IP67-rated enclosure to protect against harsh environment. All I/O ports are M12 type connectors which can effectively achieve the purpose of waterproof and dustproof. The isolated DC-in specification enhances the security protection.

|