Deploying high-performance and purpose-built platforms to actualize the smart factory

Smart manufacturing operations leverage digital transformation and industrial automation technologies to boost productivity and efficiency. The intellectualizing of factories automates the manufacturing process and improves the yield rate. The robotic arms controlled by high-end IPC can assemble parts accurately and quickly while the adjunctive inspection solution ensures quality. Smart factories deliver efficiency savings as well. The deployment of AMR is an unmanned solution to transport materials that allow workers to do more valuable work and keep them safe and sound in busy factories. Most important of all, with the data from the industrial control systems (ICS) being analyzed, the operations can be monitored and optimized in real time. To optimize and digitalize manufacturing, Axiomtek provides multiple intelligent computing platforms to realize unmanned operation, machine vision, motion control, and cyber security.

AMR replaces workers to transport heavy loads

From now on, moving heavy loads from point to point in a smart factory is no longer anyone’s work anymore; the Autonomous Mobile Robot (AMR) based on ROS2 is able to carry loads of materials and move autonomously, enhancing operational efficiency. Thus, the factory can minimize the number of workers and move toward full automation. When it comes to selecting a controller for an AMR, a fanless embedded system would be a reasonable fit due to its cost-effective price, rich I/O for necessary peripherals, and compact size to fit into the vehicle.

An advanced system in the most hot-selling product line from Axiomtek, the slim size and high-performance eBOX630A can make an AMR work effortlessly on the field site. An AMR requires multiple I/O for peripherals such as LiDAR and 3D cameras. The eBOX630A is based on the 11th Gen Intel® Core™ i7/i5/i3 processor, which is the first to provide powerful Intel® Iris® Xe graphics, so the data from the sensors can be offloaded to the integrated GPU while allowing the CPU to give the best performance, ensuring the sensors and actuator work seamlessly and making the movement smooth. The eBOX630A has six USB ports in total on both the front and rear sides and three 2.5G LAN ports to support various sensors

For connection and fast data transfer to the fleet management system for control and monitoring, the system is equipped with different expansion interfaces such as M.2 Key E 2230 slot and full-size PCI for wireless connection modules such as Wi-Fi Express Mini Card or 4G LTE. The system is durable and rugged; the operating temperatures range from -40°C to +60°C and it meets the IEC 60068-2-64 vibration endurance standard (3Grms STD), enabling the AMR suitable for challenging tasks.

Overseeing the operation with a solid HMI

As a bridge between the operator and systems, the HMI (Human Machine Interface) provides operators with interfaces to oversee control systems including multiple PLCs and SCADA systems. With the rise of the Internet of Things (IoT), the role of the HMI is becoming more and more critical, providing valuable insights from massive amounts of real-time data in an easily understood format. More than being user-friendly with a smooth touch screen and wide brightness range, as the on-site commanding center that transmits commands, it needs to be rugged; being water, dust, and vibration-resistant ensures smooth and non-stop operation.

Axiomtek recommends a touch panel pc that is also applicable in heavy industry, the GOT321W-521. The panel pc is based on the Intel® Core™ i7/i5/i3 processor and has a 21.5" FHD anti-scratch screen and a lightweight heatsink on the rear side. The front bezel is made of IP65-rated aluminum and it meets NEMA 4 rugged protection. The I/O interfaces include two COM, two LAN, four USB ports and one flexible I/O window for mini card expansion. The HMI can connect to PLC controllers or other field site devices via RS-485 or Ethernet. The panel pc can also function as a gateway to collect data from the edge and transmit it to the IT system. It can fit into any working environment as it supports panel mount, VESA mount, and wall mount. If the user has demanded a multi-screen display, it has one HDMI, one DisplayPort, and one VGA.

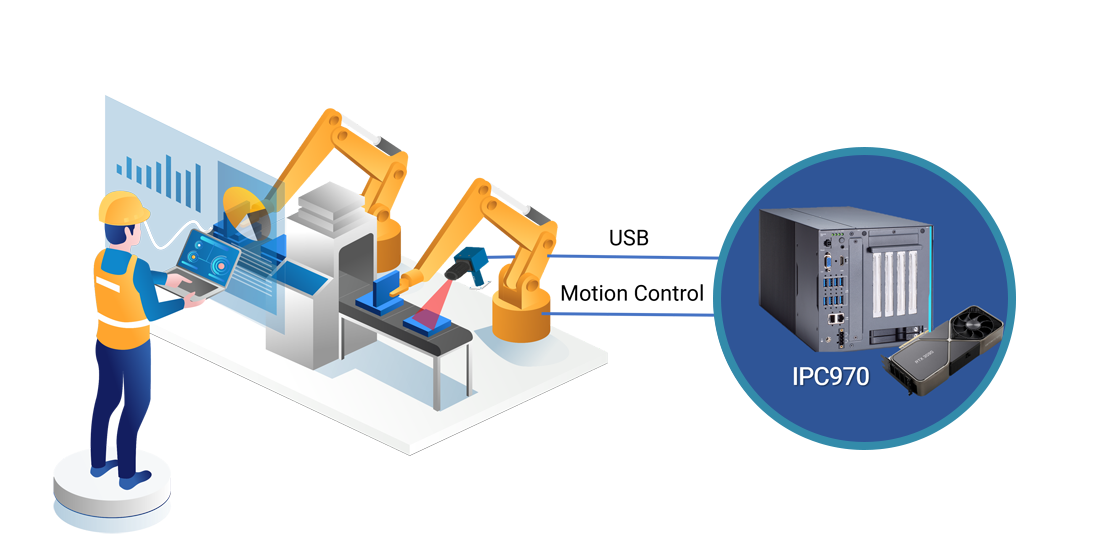

Building up smart robots and deploying machine vision with IPC

For the manufacturing industry today, robotic arms play irreplaceable roles; as they become more powerful and sophisticated than ever, they are even able to put pieces of metal frames together into a car. But since the tasks are more data-intensive when IIoT is involved, choosing IPCs for motion control gives the users many advantages. Compared with PLC or PAC, IPC has a higher computing power for machine vision and software compatibility for multiple applications like data processing. Besides, IPC has better connectivity options and more memory for a versatile role. All in all, IPC can run software-based motion control applications and automation programs on the same system to lower the cost and decrease demand for space.

Furthermore, deploying a motion control system based on IPC can make the robot more versatile and smarter; setting up a high-performance system at the edge speeds up the inferencing action. By integrating with sensors, machine vision, and cameras, the arms have more potential to perform complex tasks and co-work with other robots to perform tasks such as picking different parts and assembling them precisely. Furthermore, automated optical inspection powered by deep learning can identify slight imperfections and processing data on-site also reduces the bandwidth requirement and maintains high efficiency.

Industrial PCs have become Axiomtek’s signature and proudest products; to support various demands in advanced manufacturing applications, the design of a flexible I/O window and multiple expansion interfaces bring better compatibility for users. The lately launched IPC970 based on the Intel® Xeon® or 10th Gen Core™ i7/i5/i3 processor is a recommended choice. With DIO and COM ports on a changeable module, the IPC970 supports NVIDIA RTX3090 graphics card to boost AI performance. To transmit data gathered at the edge to the cloud or data center for analysis, the system supports different ways thanks to multiple expansion interfaces for wireless transmission, including a full-size PCIe Mini Card slot for Wi-Fi/Bluetooth/LTE modules, one M.2 Key B 3042/3050 socket for 5G wireless connection. The IPC720 provides two PCIe x4 and one PCIe x 16 for add-on features; Axiomtek also offers multiple PCIe cards to increase I/O such as PoE ports, USB ports, and digital I/O for vision, motion and data acquisition applications.

Protecting the OT network from viruses or hackers

As a large volume of data is generated on the field site for monitoring and analysis, the convergence of operational technology (OT) and information technology (IT) creates the window that the cyber-attack may jeopardize the industrial control system (ICS) and cause a halt of work and great financial loss. To protect the OT network from attack and hack, a cybersecurity gateway can be deployed like a stop-gate to implant network segregation to filter and inspect the packets.

Recently, Axiotmek just introduced a purpose-built cybersecurity gateway, the iNA200, to the market. To aggregate data and bridge OT and IT, the iNA200 is based on the Intel Atom® x6212RE/x6414RE processor (Elkhart Lake) and has the edge on its great connectivity. In addition to two COM ports, it also provides two LAN and two 2.5G LAN ports for high bandwidth with LAN bypass; for wired connection at a further distance, it has two 1G SFP ports. Moreover, it provides an M.2 Key B slot to support 5G connectivity. It sets up firewalls for data filtering and intrusion prevention. To ensure non-stop protection, the 9 to 36 VDC power supply is equipped with two terminal blocks for redundant backup input.